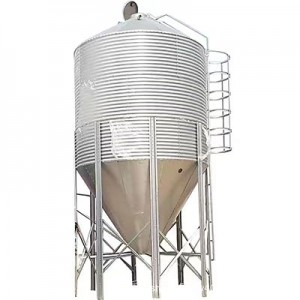

Customizable capacity of hot dip galvanized poultry feed tower

With zinc towers 5 tons, 10 tons, 15 tons, 20 tons, 25 tons, 30 tons of galvanized tower is mainly used for pigs, chickens, according to the requirements can be customized and tonnage, in the farm, farm pollution class was once clear clean, also easy to breed, leading to illness. Gradually increased along with the use of pig equipment farms and farm use galvanized towers also gradually more up, indirectly shows the farms use zinc towers is has many advantages.

With the advanced numerical controlled equipment , the silos are equipped with low product data error ,high precision and the leading stability of international standard. We select dedicated outdoor galvanized plate,which has the advantage of corrosion resistant and long life span. The adoption of international advanced technology and the unique angle design ensure feed drop more smoothly.

The silo consists of main capsule, flip, ladders, columns and other components. the main capsule uses 275g/㎡, double hot dip galvanized sheet steel, has a lower conical holes to view the feed level. The silo volume depends on different actual combinations. Hoarding water in a slope, in the hoardings at the bottom flange, so that rain water away from the cutting area. Provide weather protection , regardless of the weather. the next round head screw connection cone inside, effectively reducing cutting resistance. Upper and lower cone by pressure off treatment,both to improve the cone and strength of cone bottom's overall, but also conducive to bilateral clay bar installation , enhanced sealing.